-

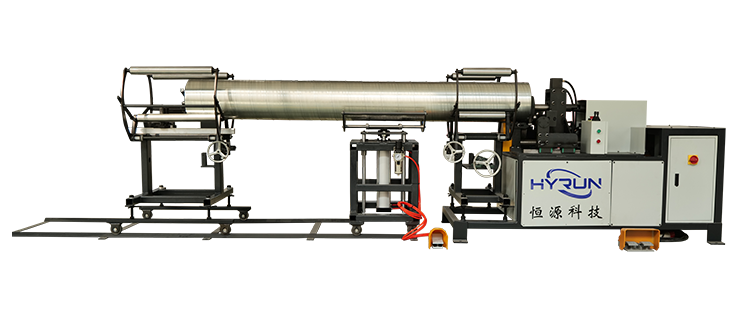

Tube Mold Spiral Duct Machine

Tube Mold Spiral Duct Machine

-

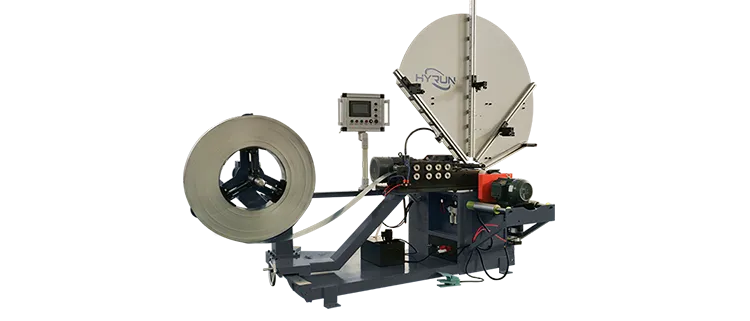

Steel Belt Spiral Duct Machine With 4 Sets Forming Rollers

Steel Belt Spiral Duct Machine With 4 Sets Forming Rollers

-

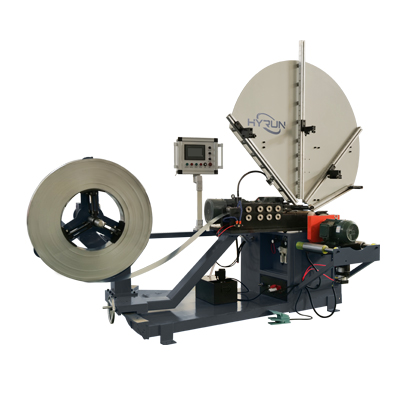

Steel Belt Spiral Duct Machine With 6 Sets Forming Rollers

Steel Belt Spiral Duct Machine With 6 Sets Forming Rollers

-

Spiral Duct Flanging Machine

Spiral Duct Flanging Machine

-

Pneumatic Spot Welding Machine

Pneumatic Spot Welding Machine

-

Seam Stitch Welding Machine

Seam Stitch Welding Machine

-

Straight Seam Automatic Welding Machine

Straight Seam Automatic Welding Machine

-

Duct Connection Welding Rack

Duct Connection Welding Rack

-

4-Roller Plate Rolling Machine

4-Roller Plate Rolling Machine

-

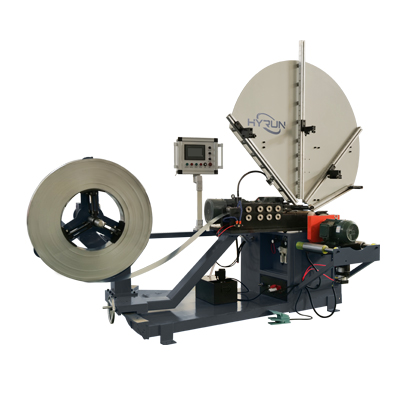

Reel Machine

Reel Machine

-

Round Duct Flange Punching Machine

Round Duct Flange Punching Machine

-

Round Flange Welding Machine

Round Flange Welding Machine

-

Asymmetrical 3-Roller Bending Machine

Asymmetrical 3-Roller Bending Machine

-

Hydraulic Rolling Machine

Hydraulic Rolling Machine

-

Hydraulic Flange Forming Machine

Hydraulic Flange Forming Machine

-

Round Duct Flange Forming Machine

Round Duct Flange Forming Machine

-

Hydraulic Elblow Machine

Hydraulic Elblow Machine

-

Electric Elbow Duct Machine

Electric Elbow Duct Machine

-

Oval Duct Machine

Oval Duct Machine

-

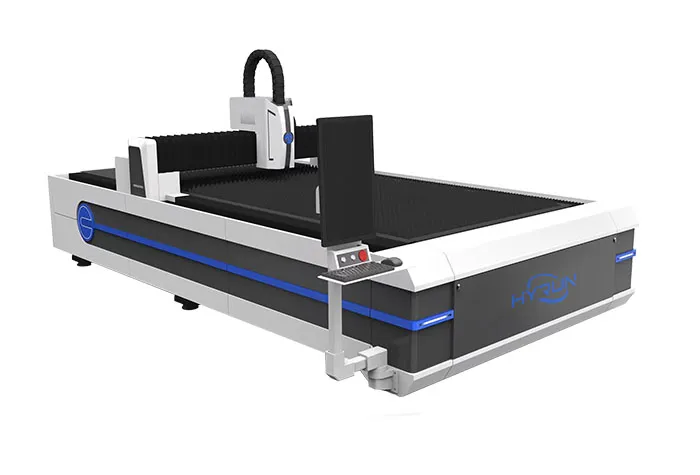

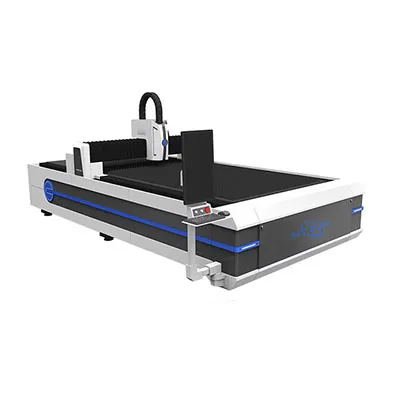

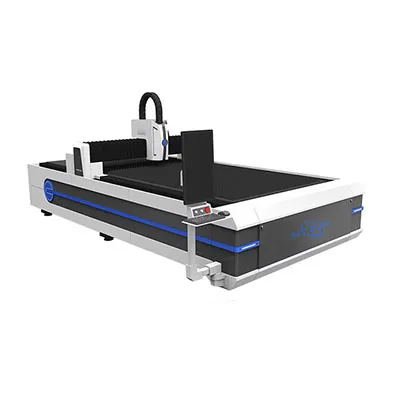

CNC Laser Cutting Machine

CNC Laser Cutting Machine

-

Round Duct Seam Closing Machine

Round Duct Seam Closing Machine

-

Hydraulic Round Duct Edge Forming Machine

Hydraulic Round Duct Edge Forming Machine

-

Spiral Duct Edge Forming Machine

Spiral Duct Edge Forming Machine

-

Tube Mold Spiral Duct Machine

Tube Mold Spiral Duct Machine

-

Spiral Duct Flanging Machine

Spiral Duct Flanging Machine

-

Steel Belt Spiral Duct Machine With 4 Sets Forming Rollers

Steel Belt Spiral Duct Machine With 4 Sets Forming Rollers

-

Steel Belt Spiral Duct Machine With 6 Sets Forming Rollers

Steel Belt Spiral Duct Machine With 6 Sets Forming Rollers

-

Auto Duct Line 5

Auto Duct Line 5

-

Auto Duct Line 3

Auto Duct Line 3

-

Pneumatic Folding Machine

Pneumatic Folding Machine

-

Lock Forming Machine

Lock Forming Machine

-

Grooving Machine

Grooving Machine

-

TDF Flange Forming Machine

TDF Flange Forming Machine

-

Square Duct Seam Closing Machine

Square Duct Seam Closing Machine

-

Hydraulic Seam Closing Machine

Hydraulic Seam Closing Machine

-

Corner Binding Machine

Corner Binding Machine

-

Corner Production Line

Corner Production Line

-

TDC Flange Forming Machine

TDC Flange Forming Machine

-

Electric Seam Closing Machine

Electric Seam Closing Machine

-

Angle Steel Flange Welding Machine

Angle Steel Flange Welding Machine

-

Round Flange Welding Machine

Round Flange Welding Machine

-

Pneumatic Spot Welding Machine

Pneumatic Spot Welding Machine

-

Seam Stitch Welding Machine

Seam Stitch Welding Machine

-

Straight Seam Automatic Welding Machine

Straight Seam Automatic Welding Machine

-

Duct Connection Welding Rack

Duct Connection Welding Rack

-

Electric Shearing Machine

Electric Shearing Machine

-

Angle Steel Punching Machine

Angle Steel Punching Machine

-

CNC Press Brake

CNC Press Brake

-

CNC Laser Cutting Machine

CNC Laser Cutting Machine

-

Asymmetrical 3-Roller Bending Machine

Asymmetrical 3-Roller Bending Machine

-

Hydraulic Rolling Machine

Hydraulic Rolling Machine

-

Pneumatic Folding Machine

Pneumatic Folding Machine

-

Lock Forming Machine

Lock Forming Machine

-

4-Roller Plate Rolling Machine

4-Roller Plate Rolling Machine

-

Reel Machine

Reel Machine

-

Round Duct Flange Punching Machine

Round Duct Flange Punching Machine

-

Grooving Machine

Grooving Machine

-

Hydraulic Round Duct Edge Forming Machine

Hydraulic Round Duct Edge Forming Machine

WHAT ARE YOU LOOKING FOR?